Kunyangwe iri yepamusoro-soro panyaya yemhando yezvigadzirwa uye otomatiki yekugadzira zvichienzaniswa nenzira dzekuisa nekuisa mabrazing, kuchine zvakawanda zvinokanganisa mukushanda zvakanaka kwekupisa uye kudzivirira kuunganidzwa kwemadota emachubhu ane mafine akasungirirwa nefrequency yakawanda nekuda kwezvinhu zvakaita sekuoma kwekubatanidza nemidzi yemachubhu ane mafine akasungirirwa nefrequency yakawanda uye mitsetse mumidzi.

Chubhu ine finned imhando yechinhu chinochinjana kupisa. Kuti kuvandudza mashandiro ekutamisa kupisa, pamusoro pechubhu inochinja kupisa kazhinji inowedzera nekuwedzera zvimbi kuti iwedzere nzvimbo yekunze (kana nzvimbo yemukati) yechubhu inochinja kupisa, kuitira kuti chinangwa chekuvandudza mashandiro ekutamisa kupisa chive chechubhu yakadaro.

Sechinhu chinochinjana kupisa, chubhu iyi inoshanda kwenguva yakareba pasi pemamiriro ekupisa kwakanyanya, senge boiler heat exchanger ine chubhu iyi munzvimbo ine hukasha, tembiricha yakakwira uye kumanikidzwa kwakawanda uye munzvimbo ine ngura, izvo zvinoda kuti chubhu iyi ive nezviratidzo zvepamusoro zvekushanda.

1), Kurwisa ngura

2), Kudzivirira kusapfeka

3), kudzivirira kubatwa kwakaderera

4), Kugadzikana Kwakakwirira

5), Kugona kwekudzivirira guruva

Mabhenefiti esimbi isina ngura akasungirirwa nelaser.

1. Uchishandisa tekinoroji yekupisa nelaser, kukwesha kwakatenderedza chidimbu kunopedzwa panguva imwe chete, uye mwero wekukwesha wechidimbu chechubhu unosvika 100%.

2. Kubatanidza neLaser musanganiswa wesimbi, simba rekusanganisa repepa rechubhu rinogona kusvika kupfuura 600MPa.

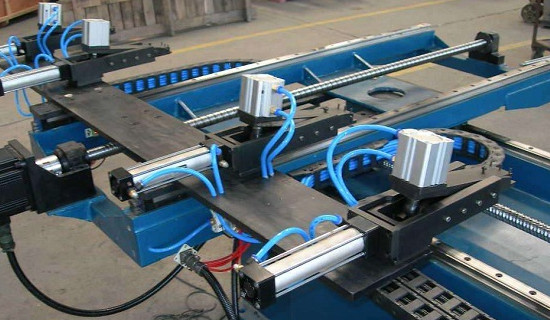

3. Muchina we laser welding unogamuchira sisitimu yekutumira servo, kunyatso fambisa kunogona kusvika padanho reKumi.

4. Kureba kwechubhu ye laser welding fin kunogona kuva ≤ 2.5mm, nzvimbo yekupisa kupfuura chubhu ye welding ine frequency yakakwira (daro rechikamu ≥ 4.5mm) yakawedzera neinenge 50%, zvinhu zvinodyiwa zvishoma pachikamu chimwe nechimwe, zvinogona kuderedza zvakanyanya vhoriyamu yekupisa.

Nguva yekutumira: Gunyana-30-2022