High Quality CNC Turret Punch Machine

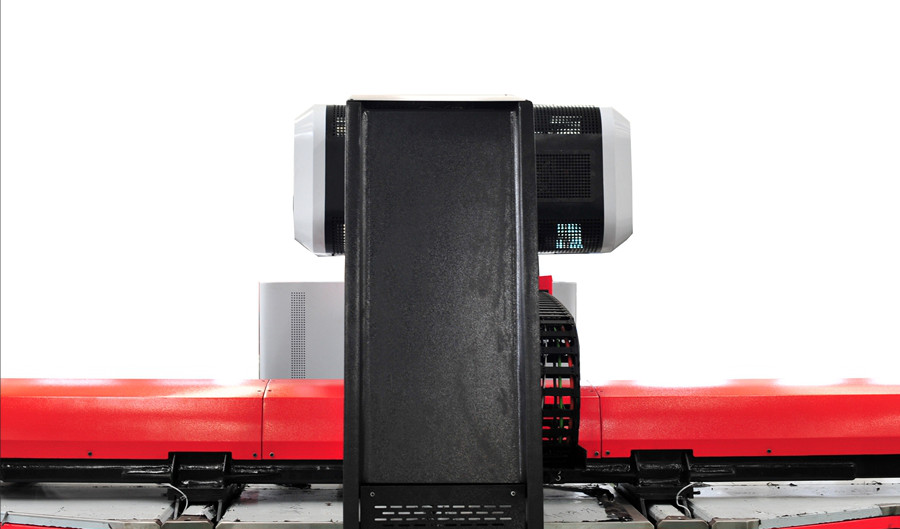

1. Single servo motor driven system, inotora torque hombe inotyairwa servo mota uye dhiraivha unit ine yakakwira yakawandisa kugona kuona yakaderera simba rekushandisa, yakanyanya kutapurirana, kuita kwakavimbika uye kugadzirisa kuri nyore.

(1) Kumhanya kunochinjika uye sitiroko

a. Iyo punch stroke inogona kusarudzwa zvichienderana nehupamhi hwepepa otomatiki, kuvandudza kushanda kwekushanda.

b. Iyo punch yekumhanyisa inogadziriswa panguva yega yega chiteshi chimwe nechimwe,

c. muchina unogona kuona kumhanyisa kumhanya panguva yekumhanya isina chinhu uye yakaderera kumhanya panguva chaiyo punch, nenzira iyi, iyo punch mhando inogona kuvandudzwa zvinobudirira, uye hapana ruzha panguva ye punch.

(2). Iyo sisitimu inoratidzira ne-yazvino-yekudzivirira uye mechanic overload kudzivirira zvishandiso.

(3). Iyo punch simba inogona kugadziridzwa otomatiki zvichienderana neshizha ukobvu uye gondohwe rinomhanya kumhanya kuita kuti punching quality isvike padanho repamusoro.

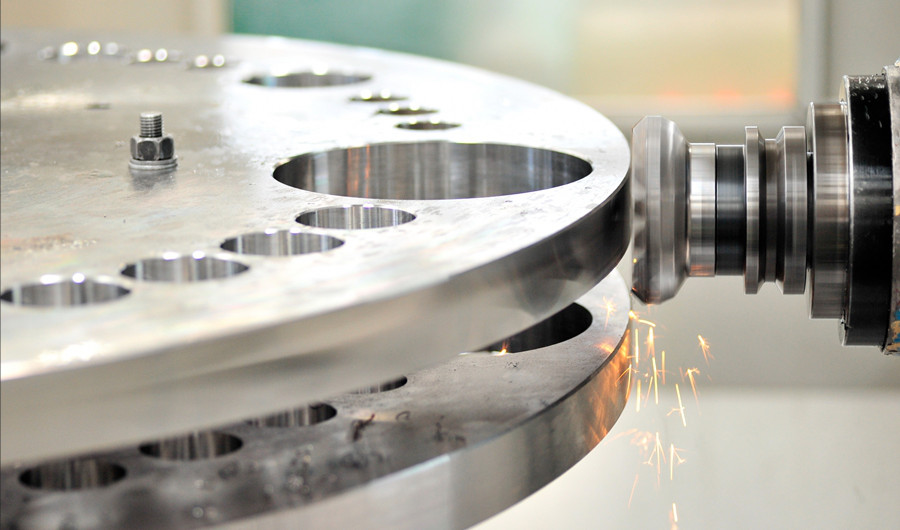

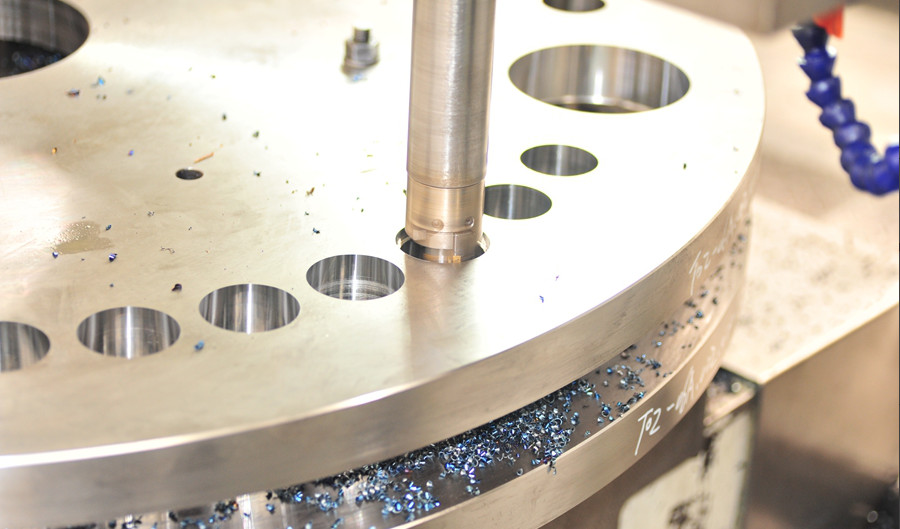

2. Iyo turret ine bushing ndeye process in pairs

Iyo turret inogadziriswa neyakakosha mudziyo kuti ive nechokwadi che coaxiality yekumusoro uye yakaderera turret uye kuwedzera hupenyu hwebasa rekushandisa; iyo bushed turret inorerutsa iyo turret chimiro kuwedzera hupenyu hwesevhisi; Kureba kwekushandisa kunogona kushandiswa kuwedzera kurongeka kwekutungamira uye kuwedzera hupenyu hwesevhisi yekushandisa (yeshizha gobvu).

3. Inotengeswa kunze kwepneumatic, lubricating uye magetsi zvikamu zvinovimbisa kuvimbika kwemuchina wose.

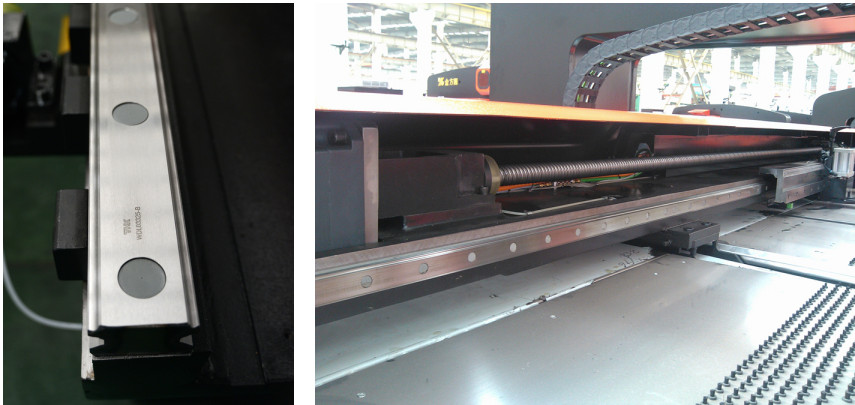

4. Hombe inotungamira gwara uye ballscrew kubva kuJapan kana Germany inova nechokwadi chekudyisa kwakanyanya.

5. Hard brashi uye bhora rakasanganiswa worktable inoderedza ruzha uye vibration panguva yekumhanya uye inodzivirirawo pepa repamusoro.

6. O-type welded furemu yakazunguzwa kaviri, kushushikana kwakadzimwa zvachose. Iyo furemu inogadziriswa neGermany SHW dual-side pentahedron processing centre panguva imwe chete, hapana chikonzero chekugadzira kechipiri chinzvimbo.

7. Chibatiso chinoyangarara chine simba guru rekusunga chinovimbisa kudya kwakagadzikana; ngoro yakabatanidzwa inovimbisa kuomarara uye kufamba kuri nyore kwembambo.

8. Iyo sisitimu inoratidzirwa nebasa re otomatiki clamp kuchengetedza kudzivirira kukuvadzwa kwechishandiso uye kusungirira, kuve nechokwadi chekuenderera mberi kwechirongwa.

9. Iyo auto-indekisi inotora yakakwirira yakaringana vhiri vhiri uye worm mechanism, kuve nechokwadi chepamusoro chakanyanya indexing. Iye Max. tooling dhayamita inogona kusvika 88.9mm uye auto-index inogona kuwedzerwa kusvika 4 nos.

10. Yakabatanidzwa danda chimiro kuita ngoro uye danda kuita chikamu chimwe, kuwedzera kuomarara uye kunounza iyo chaiyo chinzvimbo. Muchina uyu unogona kumhanya zvakanyanya kugadzikana panguva yekumhanyisa kudya uye unomisa kutsauka kweX uye Y maaxes.

. Y axis: servo mota inotyaira yakananga rack yekudyisa iyo yakabatana neyemuchina gwara, kupatsanurwa mhando danda inogadziriswa nereki yekudyisa, uye simba rekuita rinozoendeswa kumuchina furemu & pasi kuburikidza nekudyisa rack uye gwara kuitira kudzikisa kuzvidedera kwedanda. Ichi chimiro chinoratidzwa nehunhu hwekusimba kwakanaka, kujeka muhuremu, kuderera kwesimba rinokwevera zvinhu pasi, uye yakanaka simba remhinduro muhurongwa hwese hwekudyisa, kumhanya kwakadzikama uye kwakanaka chaiko.

12. Central lubrication system inogamuchirwa kutumira mafuta ekuzora kune imwe nzvimbo yekuzora zvakananga, kuderedza kupesana kwega rega rekushanda uye kuwedzera hupenyu hwebasa.

13. Anti-sheet-deformation switch uye sheet-anti-stripping switch inogamuchirwa.

| Aihwa. | Zita | Qty. | Remark |

| 1 | Packing List | 1 set | |

| 2 | Quality Certificate | 1 set | |

| 3 | Mechanic Operation Manual | 1 set | |

| 4 | Electrical Operation Manual | 1 set | |

| 5 | Foundation drawing | 1 set | |

| 6 | Yemagetsi Principal Drawing | 1 set | |

| 7 | Auto-program Software System Documents | 1 set | |

| 8 | DBN Electrical Principal Drawing | 1 set | |

| 9 | Tooling manual | 1 set | |

| 10 | CNC system manual | 1 set | |

| 11 | Tooling Drawing | 1 set |

| Aihwa. | Zita | Gauge | Qty. |

| 1 | Dual-head Spanner | 5.5×7-22×24 | 1 set |

| 2 | Moveable Spanner | 200 | 1 kwete. |

| 3 | Socket Head Spanner | S1.5-S10 | 1 set |

| 4 | Cross Screwdriver | 100 × 6 | 1 kwete. |

| 5 | Gira Pfuti | HS87-4Q | 1 kwete. |

| 6 | Girai Lubrication Pombi Compressor Pfuti | SJD-50Z | 1 kwete. |

| 7 | High pressure pfuti | 1 set | |

| 8 | T shape knob | M14×1.5 | 1 kwete. |

| 9 | Switch yenzira | M12 PNP SN = 2 yakavhurwa | 1 set |

| 10 | Switch yenzira | M12 PNP SN=2 pedyo | 1 kwete. |

| 11 | Spanner | T09-02,500,000-38 | 1 kwete. |

| 12 | Spanner yegasi cylinder switch | 1 set | |

| 13 | Nyeredzi yakapfava | Ø 12 | 1 kwete. |

| 14 | Pini yepini yakapfava | KQ2H12-03AS | 1 set |

| 15 | Zvikamu zvenheyo | 1 kwete. |

| Aihwa. | Zita | Gauge | Qty. | Remark |

| 1 | Clamp gear board | 3 nhamba. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Clamp portective board | 6 nhamba. | T02-20A.000.000-09C Kana T02-20A.000.000-23A | ||

| 2 | Spring Diki screw in clamp | M4x10 | 20 nhamba. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | screw in clamp Inner screw | M8 x 1 x 20 | 20 kwete. | |

| 4 | Kuveura badza | 30T | 2 nhamba. | T09-16.310,000-0.1.2 |

| 5 | Inner screw | M8 x 1 x 20 | 4 nhamba. |

FANUC CNC system ndiyo yakasarudzika CNC sisitimu yakagadziridzwa neJapan FANUC kunyanya nechinangwa chekusangana nemhando yerudzi urwu rwemuchina, kuvandudza kuvimbika kwemuchina kusvika pamwero mukuru.

Ini, Maitiro eSystem

1. Graphic uye punch basa;

2. Yakanaka universal G code chirongwa chekushanda kuri nyore;

3. Universal RS232 yakajairika chiteshi kutaurirana nekombuta zviri nyore;

4. Yepamberi yakazara dhijitari servo mota uye servo system;

5.10.4 ″ LCD ine mavara kuratidza;

6. Pulse encoder semi-loop mhinduro;

7. EMS ndangariro: 256K;

8. Purogiramu yemunda, purogiramu yehofisi;

9. Kuratidzwa kweChinese neChirungu;

10. Basa remifananidzo yekufananidza;

11.Imwe hombe yakakura PCMCIA kadhi ye backup ye system parameter, manera kudhirowa uye kugadzirisa chirongwa, uye kuona iyo online maitiro ehombe kugona kugadzirisa chirongwa;

12. Kuwedzera mune diki yuniti, nzvimbo yekuona ad servo control kuona kumhanya kwakanyanya uye yakakwirira chaiyo kushanda;

13. Bhatani rekushanda papaneti rinogona kutsanangurwa maererano nezvinodiwa chaizvo;

14. Super high speed clutch data cables ine tambo shoma yekubatanidza;

15. Kubatanidzwa kwepamusoro, software yakakosha. Nguva pfupi yekutanga, iyo data haizorasikike kana simba rikaperevedza kugovera kamwe kamwe;

16. Kuchengetwa kwezvikamu zve400 zvepurogiramu.

1. Matembo ane mutsara: X, Y maekisi, matemo anotenderera: T, C axes, punch axis: Z axis;

2. Alamu yekukanganisa kwemagetsi senge over-stroke.

3. Basa rekuzviongorora.

4. Basa remuganho wakapfava.

5. Universal G code yepurogiramu;

6. Basa rekushandisa muripo;

7. Basa rekuripira kureba kureba;

8. Basa re reverse gap muripo;

9. Basa remakodha kutsauka;

10. Basa rekuisazve;

11. Basa reAUTO, MANUAL, JOG mode;

12. Basa rekuchengetedza clamp;

13. Basa rekiyi yerejista yemukati;

14. Basa rechirongwa cheparameter;

15. Basa re-sub-program;

16. Basa rekukurumidza kumira uye punch lock;

18. Basa reM code;

19. Mhedziso uye purogiramu yekuwedzera;

20. Conditioning, unconditioning jump.

Programing software sumo

Isu tinotora CNCKAD kubva kuMETALIX Kambani. Iyo software ndeye yakazara seti yeCAD/CAM otomatiki programming software kubva pakugadzira kusvika pakugadzira. Iine mold raibhurari manejimendi, otomatiki modhi sarudzo yekugadzirisa, optimization yenzira uye mamwe mabasa, anogona kugadzirwa otomatiki neCAD kudhirowa NC kugadzirisa maitiro. Iwe unogona kuwana chikamu chimwe chete chirongwa, otomatiki nesting uye yakazara package.

Basa reDrawingCNCKAD mifananidzo ine simba, iri nyore uye inonzwisisika kushandisa, kuwedzera kune yakajairwa kudhirowa basa zvinoenderana nehunhu hwepepa resimbi, yakawedzera mamwe maitiro akakosha ekudhirowa akadai sekucheka, kutenderera, katatu, kona yekurudyi uye contour shape, kukanya, tarisa kugadzirisa uye kugadzirisa otomatiki, kucheka kana kudhinda, mavara echiChinese DXF/IGES/CADL/DWG file input etc.

b) Basa reKurova

Inoratidzwa ne otomatiki punch, yakakosha mold, otomatiki indexing, otomatiki kutamiswa, kucheka kumucheto, uye mamwe mabasa.

c) Basa reKuveura

Otomatiki contour tarisa uye kururamisa ma paramita emhando yemhando, ukobvu, kucheka kamwe chete, kucheka, uye kutamiswa kweshear, uye mamwe mabasa, kuisirwa ndiro otomatiki shear processing.

d) Post Processing

Otomatiki kana inopindirana kugadzirisa inovhara maitiro ese: kutsika, laser, plasma, moto, kucheka mvura uye kugaya.

Yepamberi post process inogona kuburitsa marudzi ese eanoshanda NC kodhi, inotsigira subroutine, macro chirongwa, senge optimization yenzira yekushandisa uye kushoma kutenderera mold, jekiseni rekutsigira, vacuum suction muchina mabasa senge zvinhu uye inotsvedza block rate.

Kuendesa chirongwa kune mumwe muchina kunongoda kudzvanya zvishoma nembeva.Izvi zvakatorwa kubva kuCNCKAD post processing nzira, nekubvisa mafaira ekombuta akawandisa anoita kuti oparesheni iwedzere.

e) CNC Graphical simulation

Software inotsigira chero graphic simulation yeCNC chirongwa, kusanganisira yakanyorwa nemaoko CNC kodhi, editing process zvakare iri nyore kwazvo, software inogona kungotarisa zvikanganiso, senge akarasika paramita clamp uye kureba kukanganisa, nezvimwe.

f) Shanduko kubva kuNC kuenda kuDhirowa

Ruoko rwakanyorwa kana imwe NC kodhi, inogona kungoshandurwa kuita zvikamu zvemifananidzo.

g) Date Report

Inogona kudhinda data data, kusanganisira ruzivo rwese senge nhamba yezvikamu, kugadzirisa ruzivo rwakadai senguva, mold set etc..

h) DNC Transmission

Kutora Windows interface yemodhiyo yekufambisa, kuitira kuti kutapurirana pakati pePC nemidziyo yemuchina kuri nyore.

1) 、 Tsigira aripo ese mamodheru eCNC turret punch, laser yekucheka muchina, plasma yekucheka muchina uye murazvo wekucheka muchina uye mamwe maturusi emuchina.

2) 、 Tsigira maitiro ese eCNC mashandiro emidziyo, kusanganisira kudhirowa, otomatiki kana kupindirana kugadzirisa, post processing, CNC simulation chirongwa, manual uye otomatiki kucheka, NC faira kurodha uye kurodha nezvimwe.

3)), Inogona kuisa zvakananga Autocad, SolidEdge, SolidWork uye CadKey nezvimwe zvinosanganisira ese ane mukurumbira CAD software yakagadzirwa nemifananidzo faira.

4) 、Software inotsigira zvakasiyana-siyana zvakasiyana-siyana zvekudzora nhamba, inogona kuisa NC zvikamu zvinogadzira mafaira emidziyo yakasiyana, yemidziyo yakawanda panguva imwe chete panguva yekugadzirisa.

Otomatiki Repositioning

Kana saizi yeplate yakakura kupfuura imwe nhanho, muchina unongozvimisikidza, uye wobva wagadzira mirairo yekumisikidza; kana mushandisi aine zvakakosha zvinodiwa, anogona kugadziridzwa kana kubviswa pamirayiridzo yavo yekumisikidza.

Automatic clamp kudzivirira

Mirayiridzo inogadzirwa nekumisikidza otomatiki iyo inogona kuita iyo clamp kudzivirira nzvimbo yakafa, kuderedza marara; ingave ndiro chikamu kana akati wandei endiro yesimbi, inogona kuona kuvharika kwekudzivirira kushanda.

Strip material processing

Kuti uderedze deformation yechinhu mukuita chitambi, iyo strip zvinhu zvekugadzirisa tekinoroji inogona kutorwa, uye kucheka chishandiso chinogona kushandiswa kumberi kana kumashure kweiyo bazi rekuraira.

Kuchekerera matekiniki

Yakasanganiswa nebasa rezvakajairwa kumucheto punching, otomatiki punching iyo inokwanisa kurovera iyo yakaputsika zvinhu zvakatenderedza kumucheto.

Kudzikama kamwe chete kunofamba otomatiki

Nemuchina unotakurika weclamp unogona kugadzirwa nesoftware otomatiki inofamba inosunga kuburikidza neNC mirairo.

Minimun die rotation

Iyo yakaderera kufa kutenderera sarudzo inogona kuderedza kupfeka kweotomatiki indexing station uye kunatsiridza kugadzirwa kwakanaka.

Basa remamwe maPunching Types

Basa remakona matatu punching, bevel punching, arc punching uye imwe yakasarudzika uye inoshanda punching nzira.

Basa reSimba Auto-Punching

Otomatiki Punching maficha anosanganisira otomatiki micro yekubatanidza, yakangwara sarudzo ye mold uye hupfumi hwekuona alarm uye mamwe mabasa.

I) Otomatiki yekucheka basa

METALIX CNCKAD ine AutoNest chikamu chinova seti yepureti chaiyo otomatiki optimization nesting software, iyo inogona kuona ese sheet simbi optimization yehunyanzvi nzira.

1. Mhepo yekupa: yakatemerwa kushanda kumanikidza kunofanirwa kunge kuri kupfuura 0.6mPa, kuyerera kwemhepo: kupfuura 0.3m3 / min.

2. Simba: 380V, 50HZ, simba rinoshanduka: ± 5%, simba remagetsi re 30T i45KVA, dhayamita yetambo yemagetsi ndeye 25mm², breaker i100A. Kana simba rekushandisa risina kugadzikana, stabilizer inodiwa, kana pane kubuda kwemagetsi, kuchengetedzwa kunodiwa.

3.Hydraulic mafuta: (SHELL) Tonna T220, Kana mamwe mafuta ekutungamira uye njanji yekuzora.

Mafuta ekuzora: 00 # -0 # Yakanyanya kudzvanywa girisi (GB7323-94), zano: pazasi 20 ° C shandisa 00 # Yakanyanya kudzvanywa girisi, pamusoro pe21 ° C shandisa 0 # Yakanyanya kudzvanya girizi

| Brand | Zita | Mashoko | Tembiricha |

| Shell | EPO | 0 # Kunyanya kudzvanywa girizi | 21°C kumusoro |

| Shell | GL00 | 00 # Kunyanya kudzvanywa girizi | 20°C pazasi |

3. Tembiricha yezvakatipoteredza: 0°C - +40°C

4. Kunyorova kwenzvimbo: hunyoro hunoenderana 20-80%RH(un-condensation)

5. Chengetedza kure nekudengenyeka kwakasimba kana kupindira kwe electromagnetism

6. Mhoteredzo ine huruva shoma, isina gasi rine chepfu

7. Gadzirira hwaro maererano nekudhirowa kwenheyo

8. Mushandisi anofanira kusarudza nyanzvi kana mainjiniya kuti adzidziswe, mamiriro edzidzo anofanirwa kunge akapedza kudzidza kuchikoro chesekondari, uye kuronga kwenguva refu.

11.Inofanira kugadzirira nheyo maererano nemufananidzo

12. Kuvhura 65mm spanner wrench, inotsigira tsvimbo afterburner, kugadzirisa hwaro hwaro.

13. Zvinopfuura 5 malita epeturu yakachena, mamvemve akawanda, pfuti, mafuta ekuzora, anenge 1 litita yekukwesha maturusi emuchina uye mold.

14 ine imwe Ф10 * 300 uye imwe Ф16 * 300 tsvimbo yemhangura yekuisa mold. Yakareba danda (fuselage uye danda zvakaputirwa zvakasiyana, asiwo kugadzirira zvikamu zvinotumirwa)

15 a dial chiratidzo (0-10mm renji), inoshandiswa kugadzirisa iyo X uye Y axis perpendicularity.

16 kana michina yasvika kufekitori, gadzirira 20T traffic kana crane yekusimudza michina

17.Kana V axis yakashongedzerwa nemvura chiller mota, ine chekuita nekutonhora median inofanira kugadzirwa, vhoriyamu i38L.

Zvimwe zvinhu zvisina kutaurwa zvinoda kumwe kududzirwa uye kurongeka

CNC Turret Punch Machine; turret punch press; cnc kubaya; turret punch machine; cnc punch press; cnc turret punch; cnc punch machine; turret punch press muchina;numerical control turret punch press;servo drive turret punch press;turret punch press for sale

| Aihwa. | Tsanangudzo | Unit | Machine Model | ||

| MT300E | |||||

| 1 | Max. Punch Force | kN | 300 | ||

| 2 | Main Driving Type | / | Imwe-motor inotyairwa | ||

| 3 | CNC System | / | FANUC CNC system | ||

| 4 | Max. Sheet Processing size | mm | 1250*5000 (ine imwe reposition) | 1500 * 5000 (ine imwe reposition) | |

| 5 | Nhamba yeClamp | Aihwa. | 3 | ||

| 6 | Max. Kugadzira Sheet Kukora | mm | 3.2/6.35 | ||

| 7 | Max. Punch Diameter per Time | mm | Φ88.9 | ||

| 8 | Main Striker Stroke | mm | 32 | ||

| 9 | Max. Punch Hit pa1mm Pace | hpm | 780 | ||

| 10 | Max. Punch Kupisa pa25mm Pace | hpm | 400 | ||

| 11 | Max. Nibbling Speed | hpm | 1800 | ||

| 12 | Nhamba yeRepositioning Cylinder | set | 2 | ||

| 13 | Nhamba yeChiteshi | Aihwa. | 32 | ||

| 14 | Nhamba yeAI | Aihwa. | 2 | ||

| 15 | Nhamba yeKudzora Axis | Aihwa. | 5(X,Y,V,T,C) | ||

| 16 | Tooling Type | / | Rudzi Rwakareba | ||

| 17 | Worktable Type | / | Pazasi 3.2mm: Yakazara bhurashi yakagadziriswa worktable (Kusimudza mabhora ekurodha anogona kuwedzerwa sesarudzo) | ||

| Pamusoro pe3.2mm: Mabhora akazara worktable | |||||

| 18 | Max. Kudyisa Speed | X Axis | m/min | 80 | |

| Y Axis | 60 | ||||

| XY Yakasanganiswa | 100 | ||||

| 19 | Turret Speed | rpm | 30 | ||

| 20 | Tooling Rotation Speed | rpm | 60 | ||

| 21 | Kururama | mm | ±0.1 | ||

| 22 | Max. Load Capacity | Kg | 100/150 yebhora worktable | ||

| 23 | Main Motor Power | kVA | 45 | ||

| 24 | Tooling mode | / | yakazvimirira kutsanya disassembly mhando | ||

| 25 | Air Pressure | MPa | 0.55 | ||

| 26 | Kushandiswa Kwemhepo | L/ min | 250 | ||

| 27 | CNC Memory Capacity | / | 512k | ||

| 28 | Clamp dead zone kuonekwa | / | Y | ||

| 29 | Sheet-anti-kubvisa Switch | / | Y | ||

| 30 | Anti-Sheet-Deformation Switch | / | Y | ||

| 31 | Outline Dimension | mm | 5350×5200×2360 | 5850×5200×2360 | |

| Aihwa. | Zita | Brand | Gauge | ||

| 1 | CNC System | FANUC | OI-PF | ||

| 2 | Servo Driver | FANUC | ASV | ||

| 3 | Servo Motor (X/Y/C/T axis) | FANUC | AIS(X,Y,T,C) Yakakosha mota yeV axis | ||

| 4 | Guideway | THK | HSR35A6SSC0+4200L (X:2500) | ||

| HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| HSR35A3SSC1+2310L-Ⅱ (Y:1500) | |||||

| 5 | Ballscrew | THK | BLK4040-3.6G0+3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ+1735LC7T (Y:1250) | |||||

| BLK3232-7.2ZZ+1985LC7T (Y:1500) | |||||

| 6 | Precise Bearing | NSK/Koyo | 25TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Pneumatic zvikamu | Matatu-akabatana | SMC | AC30A-03D | |

| Solenoid valve | SY5120-5D-01 | ||||

| Muffler | AN10-01 | ||||

| Cylinder | CP96SDB40-80-A93L | ||||

| 8 | Electrical System | Breaker | Schneider | / | |

| Contact | Schneider | / | |||