High Quality CNC Press Brake Manufacture

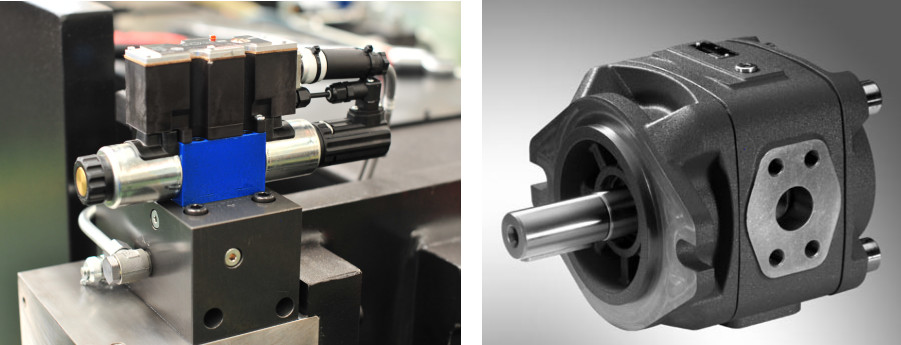

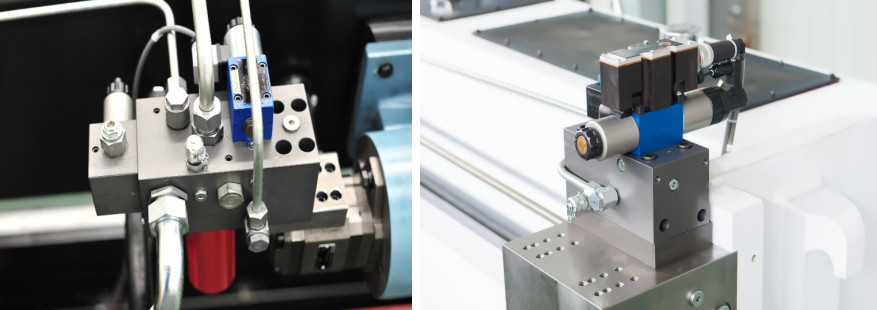

1.Electro-hydraulic system inogamuchirwa kudzora macylinders maviri kuti awane yakakwirira synchronized controling accuracy, high bending accuracy, uye repositioning accuracy.

2. Iyo mechanical deflection automatic compensation system inogamuchirwa kuti igadzirise pesvedzero ye deformation ye slider panguva yekukotama kwehutano hwebasa rekushanda. Huwandu hwemuripo hunogadziridzwa otomatiki neiyo CNC system kuti ifambise chokwadi.

(1) Muchina wacho unobhadharwa nemaitiro maviri ekugadzirisa maitiro, anogona kugutsa muripo weiyo transverse uye longitudinal kutungamira kwemuchina.

(2) Iyo dense point muripo nzira inogamuchirwa kuita kuti iko kubhenda chaiko kuve kwakanyatso.

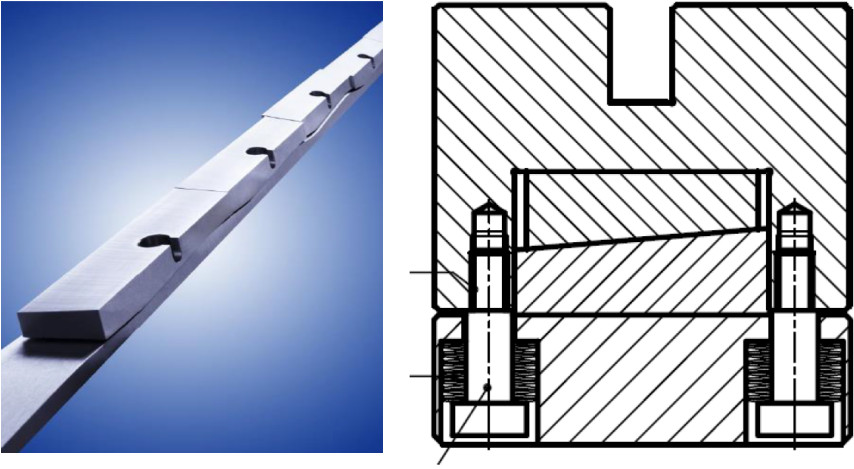

(3) kukotama kweiyo imwechete ndiro ukobvu zvinhu muripo kamwe chete panzvimbo, zvakasiyana kubva hydraulic muripo uye nekudzoka uye mberi kufamba kwechimiro, muripo wemuchina unoderedza zvakanyanya muchina chishandiso workbench kuneta deformation, kuvandudza hupenyu hwayo hwesevhisi;

(4) Shandisa yakakosha inodzikisira uye yakakwirira chaiyo potentiometer kudzora nemazvo kudzora iko kurongeka kwemuripo.

(5) Yakasiyana nematatu-ndiro chimiro che hydraulic compensating worktable, ichi chishandiso chinotora imwe-ndiro worktable dhizaini, iyo inogona kunyatso kudzivirira kupindira mukukotama workpiece.

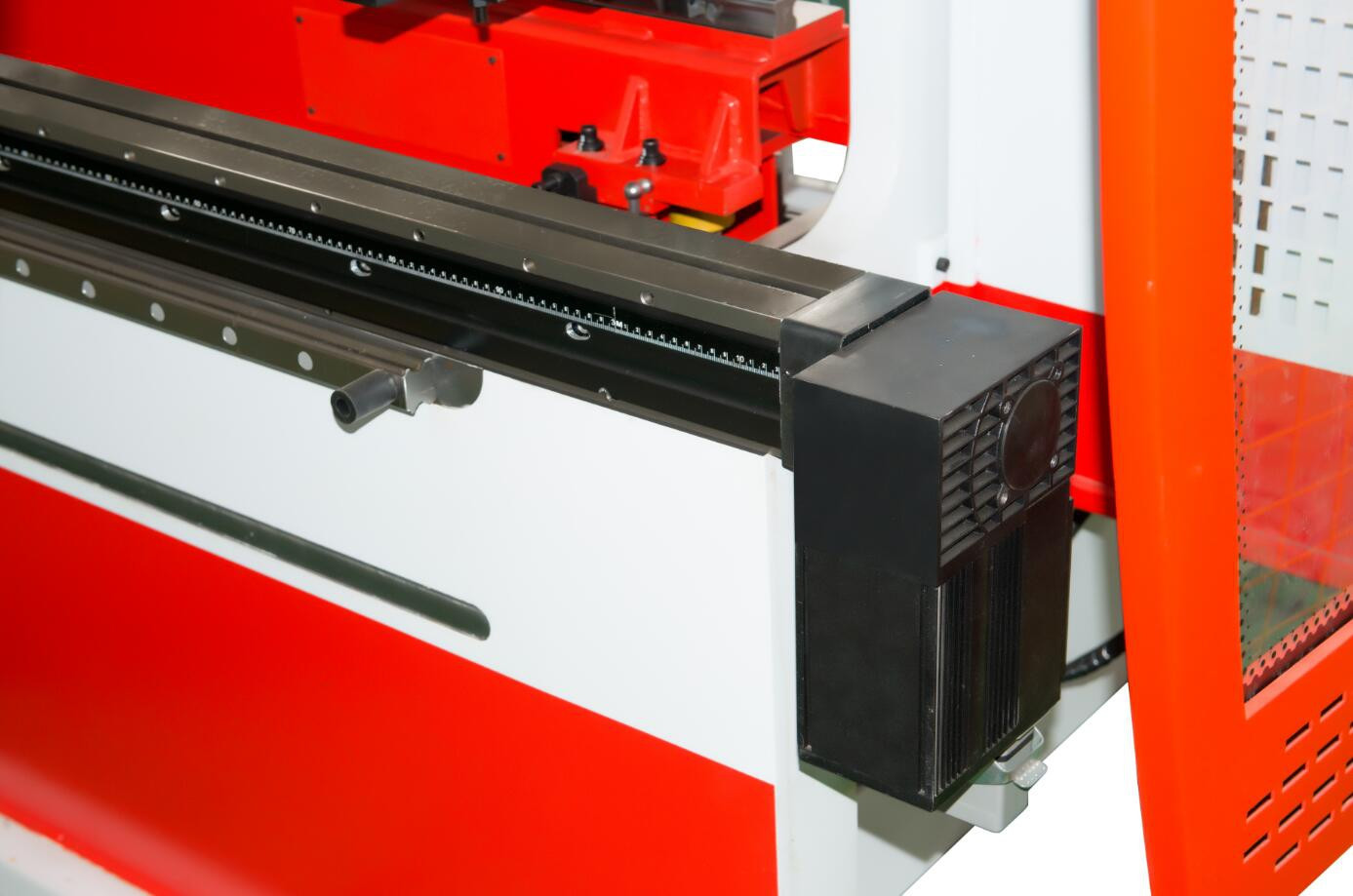

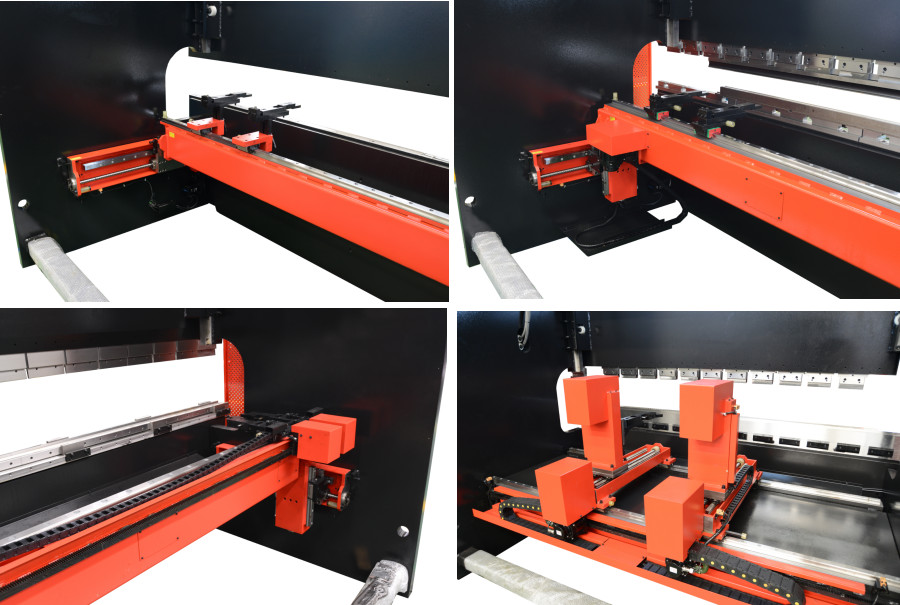

3. Multi-functional backgauge inogona kuwedzerwa kuita 6 matemo, kureva, X1 uye X2 mbezo yekumashure nekudzoka, R1 neR2 demo rekumusoro nekudzika uye Z1 neZ2 kuruboshwe nekurudyi. Iyo workpiece yekukotama inogona kuitika nyore nyore.

4. Iyo furemu inounganidzwa mune imwe nguva mushure mekucheka, inogadziriswa neCNC pentahedron processing centre, ichiva nechokwadi chekuomarara uye kugadzirisa kurongeka kwechimiro.

5. Yakabatanidzwa hydraulic controlling system inoderedza pombi, nekudaro inodzivirira kubuda kwemafuta uye inovandudza kugadzikana kwekuita, zvakare kutaridzika kwemuchina kunoyevedza.

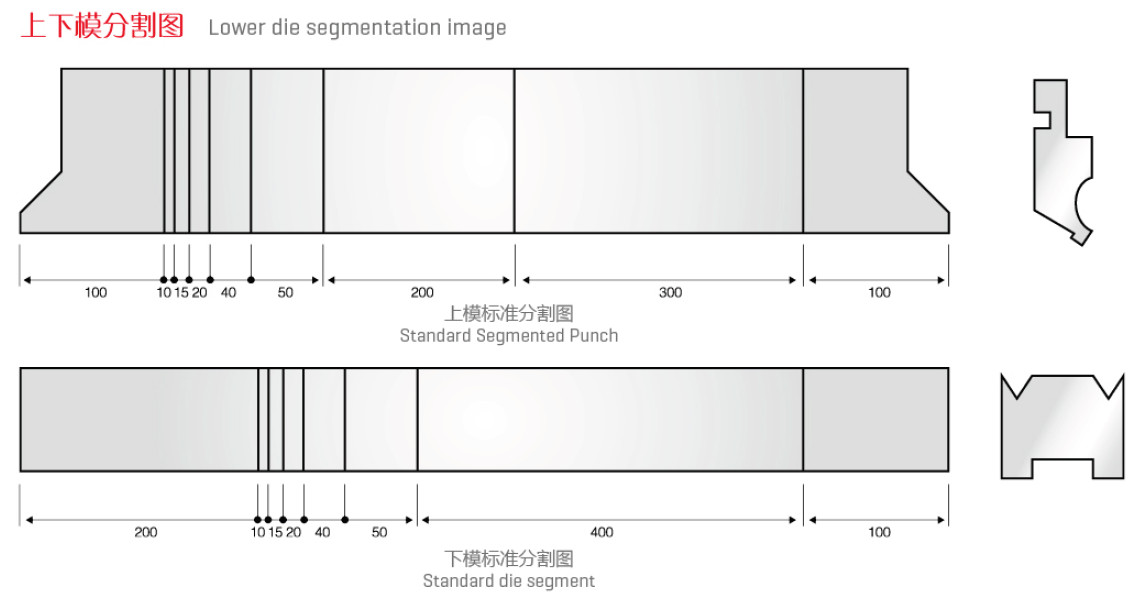

6. Segmented punch inogona kusanganiswa nehumwe hurefu maererano nekukotama kunodiwa kweakakosha workpiece.

7.Hydraulic punch auto clamping kana mechanic quick clamping inogona kugadzirirwa sechisarudzo kuderedza basa uye kuvandudza kushanda zvakanaka.

8. CNC system inotora Delem CNC system. Iyi CNC sisitimu inoratidzwa neazvino zvemagetsi dunhu, yechokwadi ruvara TFT kuratidza ine yakakwirira resolution reshiyo uye yemitauro yakawanda menyu. Ndiyo yekutanga-kirasi yekudzora sisitimu yekubhenda muchina pasi rese.

9, Iyo C mhando yehuro muripo mudziyo unoiswa pasi pehuro yemuchina wemuchina, uyo wakabatana neanoona mudziyo. Iyo diki deformation yesimba rekukotama haizokanganisa kuyerwa kweiyo sisitimu, uye iko kubhenda chaiko kwechero ukobvu uye chero ndiro yemidziyo inogona kuvimbiswa.

10, Mberi mutsigiri uye liner gidhi inoita kuti kufamba kuve nyore

Delem DA66T CNC inodzora sisitimu ine pasirese yepamusoro nhanho

1. Yakazara WINDOWS® oparesheni system, inogona kuona nekudzima muchina;

2. Kusarudzwa kwemitauro yakawanda nekushanda kuri nyore;

3. Fashoni chitarisiko dhizaini ine vanhu-yakatarisana nekushanda;

4. Yakangwara module chimiro, sisitimu inogona kukwidziridzwa kuita 24 axes;

5. 17 "TFT yechokwadi ruvara rweLCD kuratidza, 2D graphical programming;

6. Yakavakwa-mukati PLC kuderedza dhizaini yekugadzira uye kuwedzera kuvimbika;

7. USB mouse port, keyboard port;

8. Kuzviunganidzira otomatiki yemuchina wekushanda nguva uye nguva dzekukotama;

9. Kupeta maitiro otomatiki kuunganidza uye kubhenda simulation;

10. Zoom isina chitarisiko chemuchina, chishandiso uye workpiece pamwero we1: 1: 1 ine graphic fomati;

11.Digital, graphic uye dzimwe nzira dzekufa programming, flat die, big arc die, multi V groove mold, variable V groove mold;

.

13. Kukanganisa alarm system kudzivirira mal-operation;

14. Memory simba 1G

15. Remote diagnosis;

16. Machine special analysis software, real-time monitoring;

17. Special off-line programming software inogona kuderedza purogiramu nguva uye kuwedzera kushanda;

18. yakamisikidzwa faira manejimendi system, chinyorwa chinyorwa;

19. Tandem kushanda;

20. Pani yekushanda yakashongedzerwa nekumira kwekukurumidzira, bhuku rekufambisa slider uye ergonomics maonero.

T-3500TCNC system

1 Shandisa chaiyo-nguva WINDOWS inoshanda sisitimu, inogona kuona iyo pakarepo kudzima;

2 marudzi emitauro sarudzo, inogona kusetwa kune Chirungu interface, iri nyore kushanda;

3 fashoni dhizaini, iri nyore kushanda, inoratidza vanhu-vanotungamirwa;

4 yakajairika mana axis, mamwe ma modules, anotsigira anosvika matanhatu axis;

5.10 "TFT yechokwadi color screen, LCD touch screen, multi touch, maviri-dimensional graphics programming, 3D kuratidza;

6 yakavakirwa-mukati PLC basa, kuderedza redunhu dhizaini, kuwedzera kuvimbika;

7.USB mouse interface, keyboard interface;

8 otomatiki maawa ekushanda uye nguva dzekukotama;

9, dhijitari uye 2D magiraidhi akazara kubata hurongwa, kukotama maitiro 3D maonero, kukotama maitiro otomatiki kuunganidza uye kubhenda simulation;

10. Chimiro chemuchina, mold uye workpiece zvinoswededzwa zvakasununguka mu1: 1: 1 maererano nemifananidzo.

11, digital, graphic uye dzimwe nzira dzekufa programming, flat die, hombe denderedzwa arc die, multi V groove mold, variable V groove mold;

12. Kukanganisa alarm system kudzivirira mal-operation;

13. Memory simba 1G

14. Machine special analysis software, real-time monitoring;

15. yakamisikidzwa faira manejimendi system, chinyorwa chinyorwa;

16. Tandem kushanda;

.

CNC Press Brake;cnc press brake machine;cnc hydraulic press brake;cnc press brake for sale;cnc brake;hydraulic sheet metal brake;cnc hydraulic press brake machine;cnc sheet metal brake accurl press brake for sale

Holland DELEM DA52 CNC System

1 Shandisa chaiyo-nguva WINDOWS inoshanda sisitimu, inogona kuona kudzima ipapo ipapo

2. Kusarudzwa kwemitauro yakawanda nekushanda kuri nyore;

3. Fashoni chitarisiko dhizaini ine vanhu-yakatarisana nekushanda;

4. Intelligent modular structure, iyo system inogona kuwedzera iyo 4 axis inoshanduka

5. 7"TFT LCD kuratidza;

6. Yakavakwa-mukati PLC kuderedza dhizaini yekugadzira uye kuwedzera kuvimbika;

7. USB mouse port, keyboard port, RS232 port, security PLC port;

8. Kuzviunganidzira otomatiki yemuchina wekushanda nguva uye nguva dzekukotama;

9. Digital programming;

10. Digital mode mold programming;

11. Iyo otomatiki angle yekururamisa database;

12, kukanganisa yambiro hurongwa kudzivirira misoperation;

13, huwandu hwekuyeuka huri 64M;

14, yakakosha yekuongorora software, chaiyo-nguva yekutarisa;

15, Tandem kushanda;

16, pani yekuvhiya yakashongedzerwa nekumira nekukurumidza.

Holland DELEM DA53 CNC System

1 Shandisa DELEM-LINUX sisitimu yekushandisa, inogona kuona kudzima ipapo ipapo

2. Kusarudzwa kwemitauro yakawanda nekushanda kuri nyore;

3. Fashoni chitarisiko dhizaini ine vanhu-yakatarisana nekushanda;

4. Intelligent modular structure, iyo system inogona kuwedzera iyo 4 axis inoshanduka

5. 10"TFT LCD kuratidza;

6. Yakavakwa-mukati PLC kuderedza dhizaini yekugadzira uye kuwedzera kuvimbika;

7. USB mouse port, keyboard port, RS232 port, security PLC port;

8. Kuzviunganidzira otomatiki yemuchina wekushanda nguva uye nguva dzekukotama;

9. Digital touching programming;

10. Digital mode mold programming;

11. Iyo otomatiki angle yekururamisa database;

12, kukanganisa yambiro hurongwa kudzivirira misoperation;

13, huwandu hwekuyeuka huri 64M;

14, yakakosha yekuongorora software, chaiyo-nguva yekutarisa;

15. Embedded file management system, text editor

16, Tandem kushanda;

17, pani yekuvhiya yakashongedzerwa nekumira nekukurumidza.

| Aihwa. | Tsanangudzo | Quantity | Remark |

| 1 | Operations Files | One set | |

| 2 | Inner Hex Socket Spanner | One set | |

| 3 | Gira Pfuti | Imwe kwete. | |

| 4 | Grounding Bolt | One set | |

| 5 | Kugadzirisa Bolt | One set | |

| 6 | Kudzora Kwetsoka | Imwe kwete. | |

| 7 | Standard Tooling | One set |

1. Hydraulic mafuta: kunze kwenyika VG46 # anti-wear hydraulic mafuta; uye huremu hwemafuta hunodiwa hunoenderana nekutsanangurwa kwemuchina;

2. Simba: 380V, 50HZ, voltage fluctuation 10% --5%

3. Tembiricha yezvakatipoteredza: 0°C - +40°C

4. Kunyorova kwezvakatipoteredza: hunyoro hunoenderana 20-80%RH(isina-condensing)

5. Ramba kure nekwakasimba vibration sosi uye electromagnetic kukanganiswa

6. Guruva duku, hapana gasi rinokuvadza kana rinoparadza

7. Gadzirira nheyo maererano nekudhirowa kwenheyo

8. Sarudza hama yevashandi vane imwe dzidzo kumashure kwehurongwa hwenguva refu semugadziri wemuchina.

| Aihwa. | Tsanangudzo | Quantity | Remark |

| 1 | Operations Files | One set | |

| 2 | Inner Hex Socket Spanner | One set | |

| 3 | Gira Pfuti | Imwe kwete. | |

| 4 | Grounding Bolt | One set | |

| 5 | Kugadzirisa Bolt | One set | |

| 6 | Kudzora Kwetsoka | Imwe kwete. | |

| 7 | Standard Tooling | One set |

60T

| Tsanangudzo | Unit | PR9 060/2550 | |

| Max. Bending Force | KN | 600 | |

| Max. Bending Length | mm | 2550 | |

| Column Distance | mm | 2150 | |

| Huro Kudzika | mm | 350 | |

| Ram Stroke | mm | 215 | |

| Yakavharwa Urefu | mm | 530 | |

| Kusvika Speed | mm/s | 200 | |

| Kushanda Speed | mm/s | 18 | |

| Return Speed | mm/s | 200 | |

| Main Motor Power | Kw | 7.5 | |

| CNC System | Holland Delem DA66T kana DA52S kana DA53T kana T-3500T CNC sisitimu inodzora Y1, Y2, X, R, Z1, Z2 matemo uye mechanical korona. | ||

| Oiri Tangi Kukwanisa | L | 300 | |

| X Axis | Kururama | mm | ±0.1 |

| Stroke | mm | 500 | |

| Speed | mm/s | 400 | |

| Simba | Kw | 0.85 | |

| R Axis | Kururama | mm | ±0.1 |

| Stroke | mm | 200 | |

| Speed | mm/s | 200 | |

| Simba | Kw | 0.85 | |

| Z1,Z2 Axis | Kururama | mm | ±0.1 |

| Stroke | mm | 1250 | |

| Speed | mm/s | 1200 | |

| Simba | Kw | 0.75 | |

| Outline Dimension | Urefu | mm | 3400 |

| Upamhi | mm | 1400 | |

| Urefu | mm | 2510 | |

100T

| Tsanangudzo | Unit | PR9 100/3100 | PR9 100/4100 | |

| Max. Bending Force | KN | 1000 | 1000 | |

| Max. Bending Length | mm | 3100 | 4100 | |

| Column Distance | mm | 2700 | 3700 | |

| Huro Kudzika | mm | 420 | 420 | |

| Ram Stroke | mm | 265 | 265 | |

| Yakavharwa Urefu | mm | 530 | 530 | |

| Kusvika Speed | mm/s | 220 | 220 | |

| Kushanda Speed | mm/s | 17 | 13 | |

| Return Speed | mm/s | 220 | 150 | |

| Main Motor Power | Kw | 15 | 11 | |

| CNC System | Holland Delem DA66T kana DA52S kana DA53T kana T-3500T CNC sisitimu inodzora Y1, Y2, X, R, Z1, Z2 matemo uye mechanical korona. | |||

| Oiri Tangi Kukwanisa | L | 350 | 500 | |

| X Axis | Kururama | mm | ±0.1 | ±0.1 |

| Stroke | mm | 500 | 500 | |

| Speed | mm/s | 400 | 400 | |

| Simba | Kw | 0.85 | 0.85 | |

| R Axis | Kururama | mm | ±0.1 | ±0.1 |

| Stroke | mm | 200 | 200 | |

| Speed | mm/s | 200 | 200 | |

| Simba | Kw | 0.85 | 0.85 | |

| Z1,Z2 Axis | Kururama | mm | ±0.1 | ±0.1 |

| Stroke | mm | 1850 | 2800 | |

| Speed | mm/s | 1200 | 1200 | |

| Simba | Kw | 0.75 | 0.75 | |

| Outline Dimension | Urefu | mm | 3450 | 4450 |

| Upamhi | mm | 1600 | 1600 | |

| Urefu | mm | 2750 | 2710 | |

150T

| Tsanangudzo | Unit | PR9 150/3100 | PR9 150/4100 | |

| Max. Bending Force | KN | 1500 | 1500 | |

| Max. Bending Length | mm | 3100 | 4100 | |

| Column Distance | mm | 2700 | 3700 | |

| Huro Kudzika | mm | 420 | 420 | |

| Ram Stroke | mm | 265 | 265 | |

| Yakavharwa Urefu | mm | 530 | 530 | |

| Kusvika Speed | mm/s | 180 | 180 | |

| Kushanda Speed | mm/s | 11 | 11 | |

| Return Speed | mm/s | 150 | 150 | |

| Main Motor Power | Kw | 15 | 15 | |

| CNC System | Holland Delem DA66T kana DA52S kana DA53T kana T-3500T CNC sisitimu inodzora X, Y1, Y2, R, Z1, Z2 matemo uye kupfekedza korona. | |||

| Oiri Tangi Kukwanisa | L | 440 | 600 | |

| Nhamba yeTangi reOiri | Aihwa. | 3 | 4 | |

| X Axis | Kururama | mm | ±0.10 | ±0.1 |

| Stroke | mm | 500 | 500 | |

| Speed | mm | 500 | 400 | |

| Simba | kw | 0.85 | 0.85 | |

| R Axis | Kururama | mm | ±0.10 | ±0.1 |

| Stroke | mm | 200 | 200 | |

| Speed | mm | 200 | 200 | |

| Simba | kw | 0.85 | 0.85 | |

| Z1,Z2 Axis | Kururama | mm | ±0.10 | ±0.1 |

| Speed | mm | 1200 | 1200 | |

| Stroke | mm | 1850 | 2800 | |

| Simba | kw | 0.75 | 0.75 | |

| Outline Dimension | Urefu | mm | 3470 | 4470 |

| Upamhi | mm | 1720 | 1720 | |

| Urefu | mm | 2700 | 2710 | |

PR9 060

| Aihwa. | Zita | Model | Brand | |

| 1 | CNC System | DA66T/T-3500T/DA52S kana DA53T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA OR YASAKAWA | |

| 3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA OR YASAKAWA | |

| 4 | Hydraulic System | Electro-hydraulic system | Germany Bosch-Rexroth kana Germany HOERBIGER | |

| Synchronization inodzora musangano | a. pressure valve | |||

| b. inoshanda vharafu | ||||

| c. proportional servo valve nezvimwe. | ||||

| Hydraulic controlling musangano | a. cartridge valve | |||

| b. proportional pressure valve | ||||

| c. selector vharafu | ||||

| d. proportional decompress valve | ||||

| e. pressure valve etc. | ||||

| 5 | Linear gwara | 35A---760L OR 35E-760L | THK KANA PMI | |

| 6 | Ballscrew | 25/20-1000L kana R25/20-880/1000 | THK KANA PMI | |

| 7 | Pombi yemafuta | PGH3-2X/016RE071VU2 | Germany Rexroth | |

| 8 | Yakazara seti yekuisa chisimbiso muhumburumbira hwemafuta | USA PARKER | USA PARKER | |

| 9 | Yakazara seti yepipeline yekumanikidza kwakanyanya | 1.GE16 ZSR 3/4EDCF | USA PARKER、EO-2 pombi yakabatana kana Germany VOSS pombi yakabatana | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF nezvimwe. | ||||

| 10 | Coupling | R38 25/42 | Germany KTR | |

| 11 | AC contactor | LC1-D1810B7, LC1-D0910B7N nezvimwe. | Schneider | |

| 12 | Proximity switch | TP-SM5P2 nezvimwe. | TEND | |

| 13 | Terminal lead | UK2.5B,UK10N nezvimwe. | Phoenix | |

| 14 | Bhatani | XB2-BVB3LC nezvimwe. | Schneider | |

| 15 | Painting | Holland SIKKENS | ||

| 16 | Crowning | National brand( standard) | SREE/Mubatanidzwa | |

| 17 | Crowning | Zvakatorwa kunze (sarudzo) | VILLA | |

| 18 | Mutsigiri wepamberi | standard | JFY | |

PR9 100

| Aihwa. | Zita | Model | Brand | |

| 1 | CNC System | DA66T kana DA52S kana DA53T kana T-3500T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA OR YASAKAWA | |

| 3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA OR YASAKAWA | |

| 4 | Hydraulic System | Electro-hydraulic system | Germany Bosch-Rexroth kana Germany HOERBIGER | |

| Synchronization inodzora musangano | a. pressure valve | |||

| b. inoshanda vharafu | ||||

| c. proportional servo valve nezvimwe. | ||||

| Hydraulic controlling musangano | a. cartridge valve | |||

| b. proportional pressure valve | ||||

| c. selector vharafu | ||||

| d. proportional decompress valve | ||||

| e. pressure valve etc. | ||||

| 5 | Linear gwara | 35A-760L OR 35E-760L | THK KANA PMI | |

| 6 | Ballscrew | 20/25-880/1000 KANA R25/20-880/1000 | THK KANA PMI | |

| 7 | Pombi yemafuta | PGH4-3X/032RE071VU2 | Germany Rexroth | |

| IPVAP5-32 | Germany VOITH | |||

| HQI3-32 | Germany Eckerle | |||

| 8 | Yakazara seti yekuisa chisimbiso muhumburumbira hwemafuta | USA PARKER | USA PARKER | |

| 9 | Yakazara seti yepipeline yekumanikidza kwakanyanya | 1.GE16 ZSR 3/4EDCF | USA PARKER、EO-2 pombi yakabatana kana Germany VOSS pombi yakabatana | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF nezvimwe. | ||||

| 10 | Coupling | R38 25/42 | Germany KTR | |

| 11 | AC contactor | LC1-D1810B7, LC1-D0910B7N nezvimwe. | Schneider | |

| 12 | Proximity switch | TP-SM5P2 nezvimwe. | TEND | |

| 13 | Terminal lead | UK2.5B,UK10N nezvimwe. | Phoenix | |

| 14 | Bhatani | XB2-BVB3LC nezvimwe. | Schneider | |

| 15 | Painting | KAILEDI | ||

| 16 | Crowning | National brand( standard) | SREE/Mubatanidzwa | |

| 17 | Crowning | Zvakatorwa kunze (sarudzo) | VILLA | |

| 18 | Mutsigiri wepamberi | standard | JFY | |

PR9 150

| Aihwa. | Zita | Model | Brand | |

| 1 | CNC System | DA66T kana DA52S kana DA53T kana T-3500T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA OR YASAKAWA | |

| 3 | Servo Driver | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA OR YASAKAWA | |

| 4 | Hydraulic System | Electro-hydraulic system | Germany Bosch-Rexroth | |

| Synchronization inodzora musangano | a. pressure valve | |||

| b. inoshanda vharafu | ||||

| c. proportional servo valve nezvimwe. | ||||

| Hydraulic controlling musangano | a. cartridge valve | |||

| b. proportional pressure valve | ||||

| c. selector vharafu | ||||

| d. proportional decompress valve | ||||

| e. pressure valve etc. | ||||

| 5 | Linear gwara | 35A-760L OR 35E-760L | THK KANA PMI | |

| 6 | Ballscrew | 20/25-880/1000 KANA R25/20-880/1000 | THK KANA PMI | |

| 7 | Pombi yemafuta | PGH4-3X/032RE071VU2 | Germany Rexroth | |

| IPVAP5-32 | Germany VOITH | |||

| HQI3-32 | Germany Eckerle | |||

| 8 | Yakazara seti yekuisa chisimbiso muhumburumbira hwemafuta | USA PARKER | USA PARKER | |

| 9 | Yakazara seti yepipeline yekumanikidza kwakanyanya | 1.GE16 ZSR 3/4EDCF | USA PARKER、EO-2 pombi yakabatana kana Germany VOSS pombi yakabatana | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF nezvimwe. | ||||

| 10 | Coupling | R38 25/42 | Germany KTR | |

| 11 | AC contactor | LC1-D1810B7, LC1-D0910B7N nezvimwe. | Schneider | |

| 12 | Proximity switch | TP-SM5P2 nezvimwe. | TEND | |

| 13 | Terminal lead | UK2.5B,UK10N nezvimwe. | Phoenix | |

| 14 | Bhatani | XB2-BVB3LC nezvimwe. | Schneider | |

| 15 | Painting | KAILEDI | ||

| 16 | Crowning | National brand( standard) | SREE/Mubatanidzwa | |

| 17 | Crowning | Zvakatorwa kunze (sarudzo) | VILLA | |

| 18 | Mutsigiri wepamberi | standard | JFY | |

CNC Press Brake;cnc press brake machine;cnc hydraulic press brake;cnc press brake for sale;cnc brake;hydraulic sheet metal brake;cnc hydraulic press brake machine;cnc sheet metal brake accurl press brake for sale